R&D and Innovation

“Our R&D department leads the change by developing cutting-edge technologies for a greener and more sustainable future.”

R&D division is dedicated to the development of advanced technologies which will drive the transition to a sustainable energetic future and secure operation’s efficiency. Our Company is involved mostly in the field of renewable energy, actively collaborating with universities, research institutes and industrial partners. To date, we worked on several activities which addresses global energetic challenges both through experimental activities and informative events in universities.

We’re working actively in off-shore wind energy development, energy storage , CO2 capture and utilization, biogas valorization plans, asset integrity through the deployment of advanced sensors and recovery of raw materials from WEEE. We’re also actively expanding into new assets such as catalysts for hydrogen production, biofuel production and advanced diagnostics of water and district heating.

Our mission is to both help developing research project participating as partners in research calls and through asset acquisition finalized with the market deployment of new technologies.

Asset Management

Diagnostic for Aqueducts

Advanced technology is transforming infrastructure diagnostics, enabling more efficient and sustainable management. Innovative approaches like robotics and 3D modeling enhance precision, optimize resources, and improve reliability in critical systems.

At DG Impianti, in collaboration with startup Pipein, we have carried out a pilot diagnostics test on a section of decommissioned aqueduct in Basilicata (Italy), part of the Pertusillo carrier, to reconstruct a complete 3D model of the pipeline’s section. This project was awarded the CALL4INNOVATION prize by Basilicata Open LAB, an initiative promoted by ENI Joule dedicated to supporting innovation and entrepreneurship in the Basilicata Region.

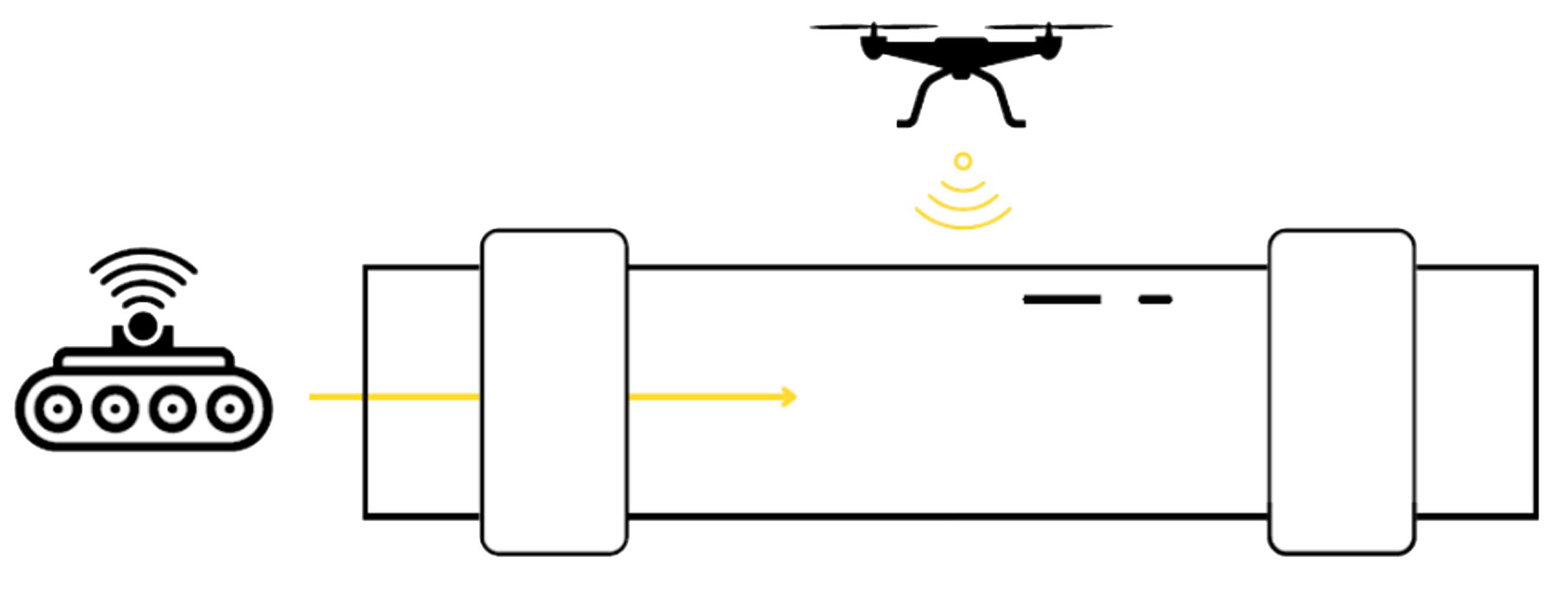

The Aqueduct Diagnostics Test integrates advanced technologies such as photogrammetry and laser scanners, using inspection robots and drones. This combination provides a comprehensive and accurate study, ideal for efficient and sustainable management of water infrastructure.

Objective

The Diagnostics Test for Aqueducts aims at developing an advanced tool for monitoring and predicting the maintenance frequency of infrastructure. It enables in-depth simulations and analysis, offering the possibility to compare results with historical data for increasingly efficient management.

Innovation

Diagnosis is based on the creation of a 3D digital model, obtained through the combination of two technologies:

- Drone photogrammetry

- Internal inspection with DDS3 Lidar 3D Robot

This methodology allows for accurate identification of residual pipe thickness, deformations, cracks, debris, internal obstructions, and sediment. Detailed visualization facilitates defect detection and enables targeted interventions, reducing time and cost. The integrated approach makes it possible to reach impervious sections, minimizing operational risks and providing a 360-degree view of the state of the aqueduct.

Role of DG

DG Impianti is a key multidisciplinary player in the development of the Diagnostic Service, ensuring high standards of innovation and quality.

Partnership

DG Impianti, Pepien, Take Over.

Technology – Innovation – 3D Modeling – Diagnostic – Future – Technology – Innovation – 3D Modeling – Diagnostic – Future –

Technology – Innovation – 3D Modeling – Diagnostic – Future – Technology – Innovation – 3D Modeling – Diagnostic – Future –

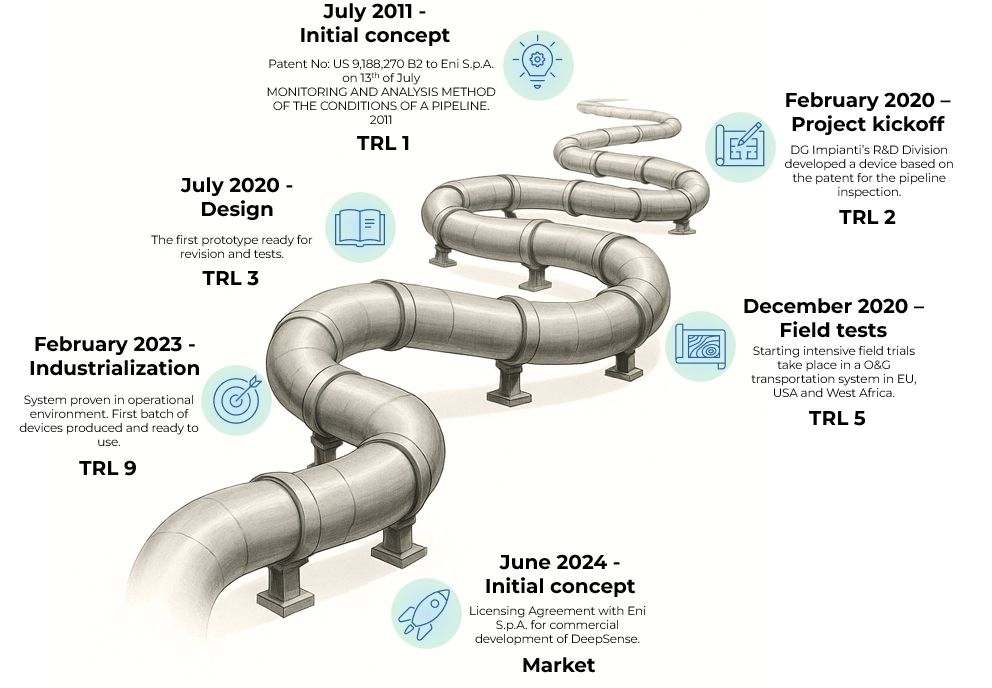

DeepSense Technology

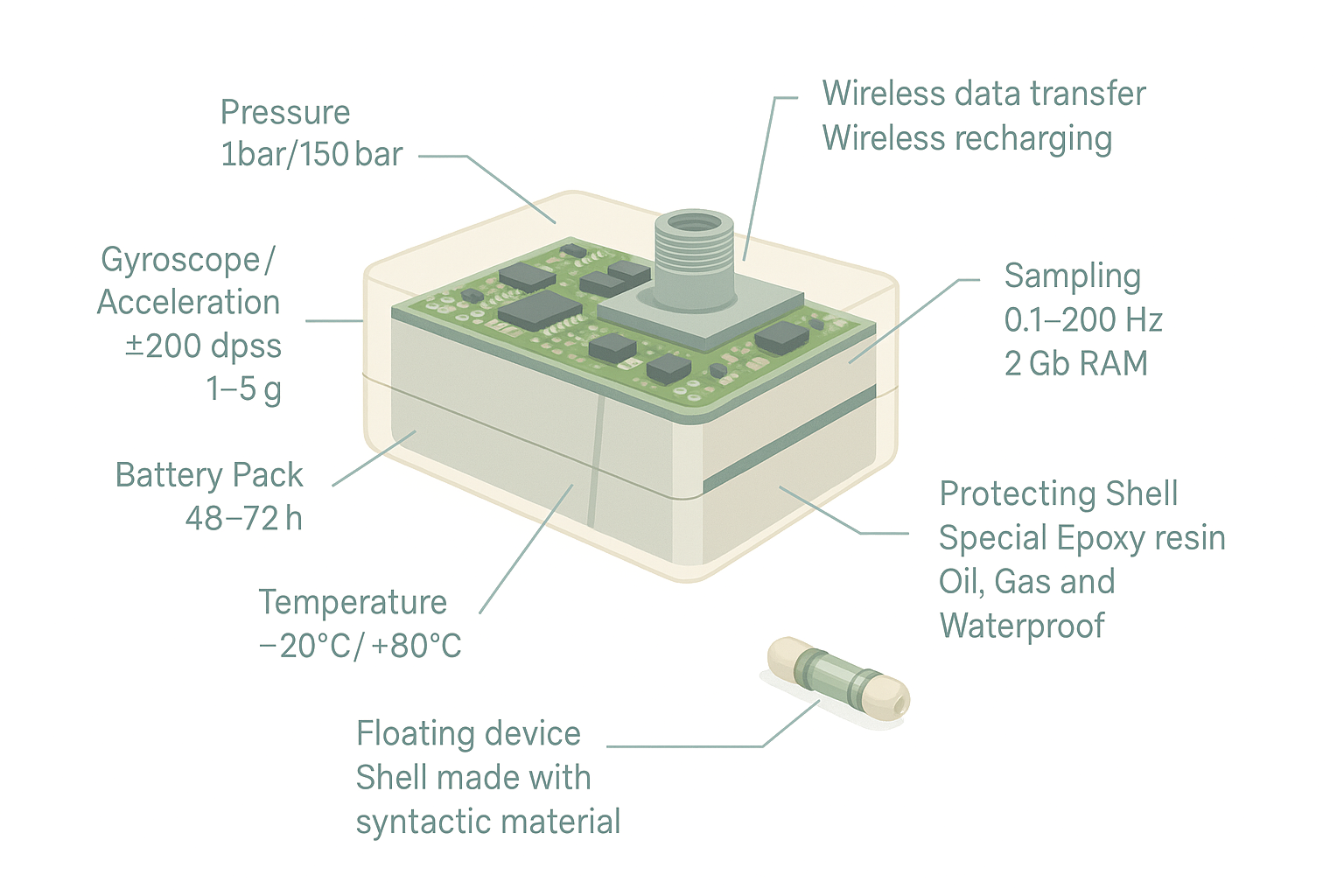

DeepSense Technology leverages advanced sensors and real-time data processing to deliver unparalleled accuracy in pipeline inspection. Our miniaturized sensors can be installed on any pig, collecting comprehensive data as they travel through the pipeline. This data is then processed in real-time using our cloud-based platform, allowing for immediate analysis and sharing.

- immediate feedback about the efficiency of a simple cleaning PIG allowing the optimization of the maintenance operations promptly

- helps prioritize which pipeline sections to inspect more closely

- allows cost-effective targeted inspections rather than full-scale checks

- can be easily applied in all the piggable pipelines with negligible impact on the operations

- data are shown is a high-resolution or vector map: the map shows more precise

- specific details for the zoomed-in area

The patented DeepSense solution will pair a multi-sensor system with machine learning and AI powered data analytics, that will evaluate and interpret massive amounts of data.

For those interested in the technical details, our sensors and software come with comprehensive specifications that ensure compatibility and performance. Download our detailed technical brochure for more information.

Web based: Any user can access the system with any PC–no need for specific software

Cloud assisted: Dataset of samples in the range of Ms (Mega samples) could be rendered

Open architecture: The system could be integrated with any external technologiesplatforms and Customer databases

46% Reduction in PIG runs – Planned pigging operations were set at 37runs, but DeepSense revealed that the pipeline was already clean after just 20 runs.

66% reduction in pigging frequency – Weekly pigging was the initial plan, but DeepSense showed that pigging every 3 weeks with a different pig type ensures effective cleaning, unlike the old weekly method.

3.500 Overall pipeline km inspected

170 Missions carried out worldwide

1000 Field tests hours.

Interested in learning more about DeepSense Technology? Contact us today for more information or to schedule a demo.

Our team is here to assist you with any questions or inquiries you may have: deepsense@dgimpianti.eu

Raw Material Recovery

Our Company is a system integrator of innovative technologies applied to raw materials recovery. We develop solutions for the recovery of CRM and precious metals from WEEE, with economically sustainable and environmentally friendly technologies. Our activities are directed both at generating new knowledge (Research) and finding applications of know-how (Technology) for companies and institutions.

HYDRO-PV Project

RAEE | PHOTOVOLTAIC PANELS | RECYCLE | CIRCULAR ECONOMY

Innovation

The process minimizes the amount of effluent leaving the plant (Minimum Liquid Discharge) and the consumption of water and chemicals, reducing the environmental impact, keeping the technology very competitive in terms of cost.

Hazardous reagents used in conventional leaching methods (such as cyanide, nitric acid, and hydrochloric acid) are replaced with alternatives that are safer for health and the environment.

Role of DG

Utilizing design and project management skills, DG Impianti emerges as a multidisciplinary entity for process and service innovation that can effectively address technology development activities.

Partnership

UNIVAQ, SWE, BFC.

Technology – Innovation – Environment – Technology – Innovation – Environment – Technology – Innovation – Environment –

Technology – Innovation – Environment – Technology – Innovation – Environment – Technology – Innovation – Environment –

Energy Transition

DG Impianti is strongly involved in the development of new research projects related to energy transition. Our efforts are focused on the industrialization of projects characterized by high Technology Readiness Level (TRL) or in the support during the development of low TRL projects. Our multidisciplinary experience is crucial during the swift development of new technologies.

Carbon capture and storage

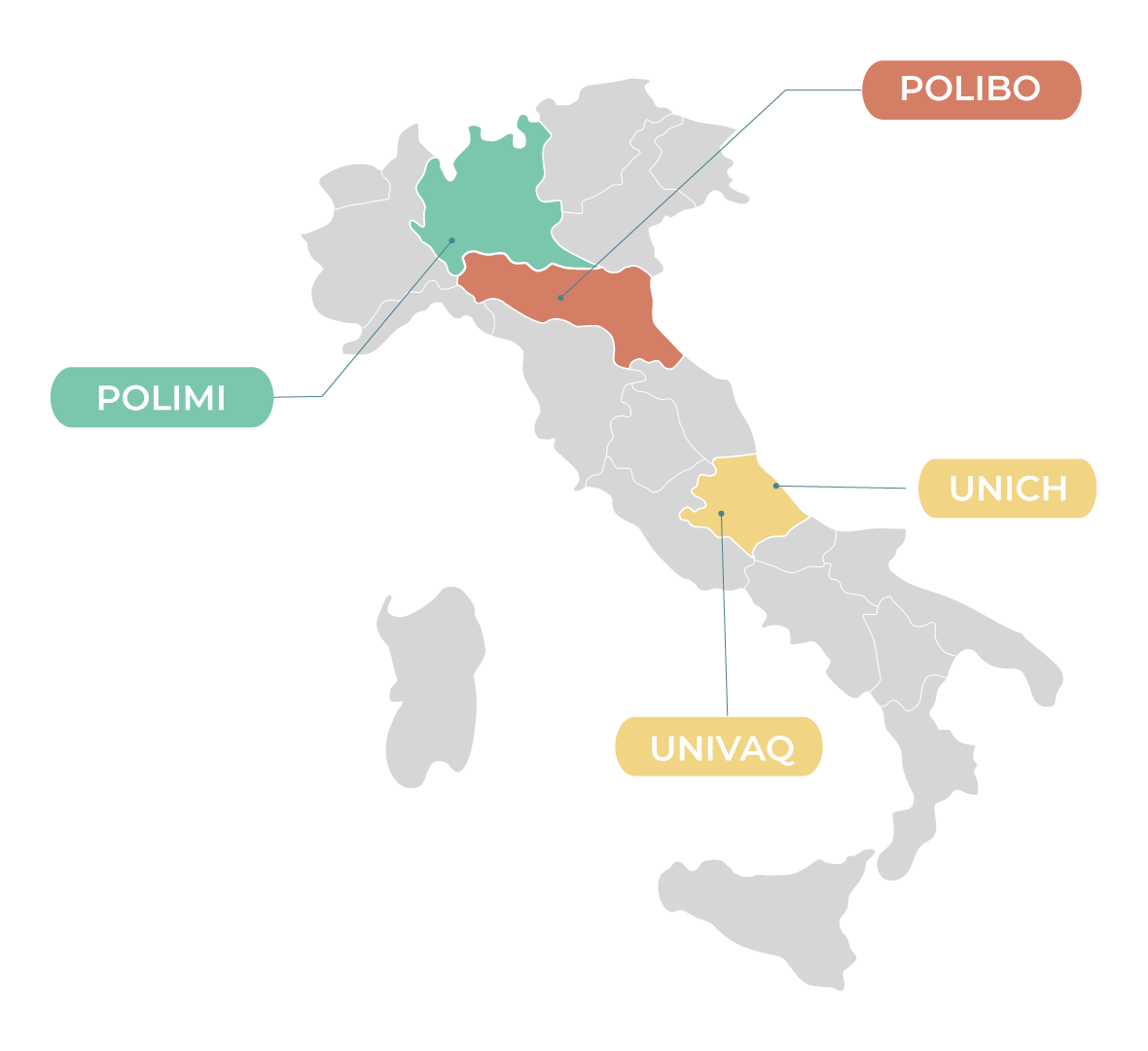

BEAST (Biogas Enrichment via Advanced Separation Techniques) – Pilot plant for biogas separation in collaboration with University “G. D’Annunzio” Chieti-Pescara and University of Messina.

Biofuels

CO2 valorization: from waste to source of added-value products by chemical reactions in green conditions.

Energy Storage and Transportation

Synthesis of low cost, waste-derived and non-noble catalysts based on advanced nanomaterials for hydrogen production, storage and transportation: UniCh.

Sustainability – Innovation – Environment – Green Energy – Sustainability – Innovation – Environment – Green Energy –

Sustainability – Innovation – Environment – Green Energy – Sustainability – Innovation – Environment – Green Energy –

Collaboration with University

At DG Impianti Industriali we believe in the power of innovation and knowledge-sharing. Through collaborations with universities, our company fosters research and development, driving advancements in engineering and technology. This partnership strengthens the bridge between academia and industry, ensuring continuous growth and forward-thinking solutions.

CO₂ Capture System

in Collaboration with the “G. D’Annunzio” University of Chieti – Pescara

The project involves the development of an innovative system for capturing carbon dioxide, both in its pure form and within gas mixtures. The system is based on a Lewis acid-base interaction mechanism, which enables the stable capture of the gas without transforming it into other compounds.

The

Setup